roughing end mill diagram

Roughing end mill Rough-cutters have notches or serrations on the cutting edge which like a mechanical shredder produces shorter easier-to-manage chips. Floating Tap Tool Holders.

Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco

The dimensions of the components are listed in Table 1.

. Optimum cutting data and tool life for maximum productivity Maximum process reliability thanks to high stability Perfectly adapted to the machining. Normally a 20 reduction in effective horsepower is used. End Mill Tool Holders.

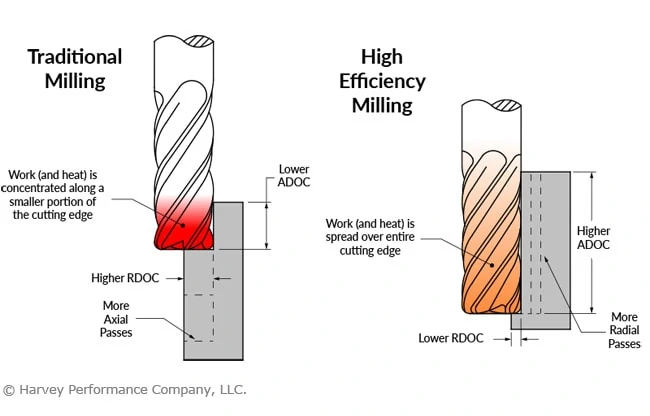

By doing this we create much less friction and HEAT in the tool which translates to longer tool life. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Tendem or Continuous mills.

Variable helix end mills reduce chatter and vibration. 3 Micron Runout at bore. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from breaking.

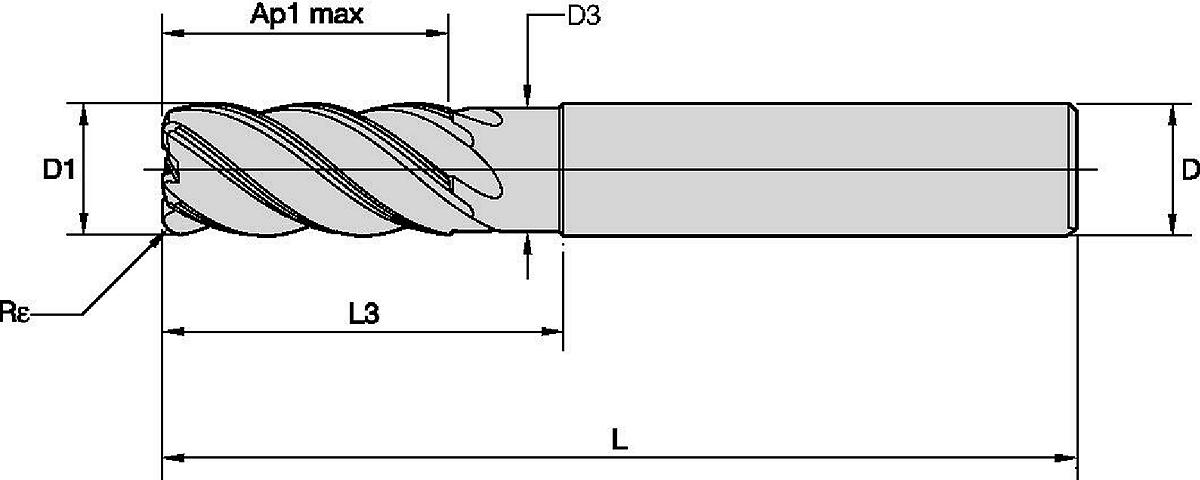

Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required. Axial Runout The difference between the highest and lowest indicator reading that is taken at the face of a cutter near the outer diameter. High-efficiency and low-chattering milling can be achieved by smooth chip removal geometry excellent flute shape with chipping resistance and suitable helix angle for aluminium milling.

Back view of roughing cut with a 65 radial step over Figures 4 and 5 show the effects of radial and axial depth of cuts on the height and width of scallops. Acceleration spectra evaluated from the data are presented in Campbell diagrams see Fig. The graphic shows a typical plunge milling operation for a square pocket courtesy of BobCAD.

The tooth design allows for little to no vibration but leaves a rougher finish. Regarding pronounced frequencies two separate ranges become apparent. For fast cuts and the greatest rigidity use shorter end mills with larger diameters.

They are recommended for. Tool Holder Collet Nut. Four high rolling mills.

Use cobalt PMPlus and carbide on harder materials and high production applications. Use cobalt PMPlus and carbide on harder materials and high production applications. Shell Mill Tool Holders.

Taper Adapter. Multiple teeth come into contact with the workpiece at the same time. They are Roughing End Mills that can achieve efficient machinig of Al-alloy used by the aircraft and other industries.

The rolls are supported in bearing housed in sturdy upright frames called stands which are grouted to the rolling mill floor. Side milling curved surface milling and drilling are possible only by one tool. Some end mills with fewer flutes are called roughing end.

These make the cutting process faster than with a regular end mill. However we have developed a rake face geometry that enables the material to curl in the outer rake face as you can see by the red arrow above. Apply coatings for higher feeds speeds and tool life.

It contains two heavy rolls fixed one over the other. Shrink Fit Tool Holders. Coarse-Pitch Roughing CPR CPR series milling cutters are coarse-pitch HSSCo8 High-Speed Steel with 8 cobalt roughing end mills.

The shaded region represents the scallop that is left behind after 2 roughing passes and runs parallel to the tool path. Variable helix end mills reduce chatter and vibration. A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone.

Square end mills are used. Apply coatings for higher feeds speeds and tool life. Diagram of solid carbide end mills Essential Summary.

Carbide Square End Mills Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Milling Chuck Tool Holders. Roughing End Mills - Cobalt and High Speed Steel Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions.

Screw-In Threaded Body Tool Holder. Heres a typical example. The cut bits of metal are smaller than usual and therefore easier to clear.

The length of tool wear of the cutting edge was about 34 μm. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep- pocket milling applications. The roughing end mill has jagged teeth.

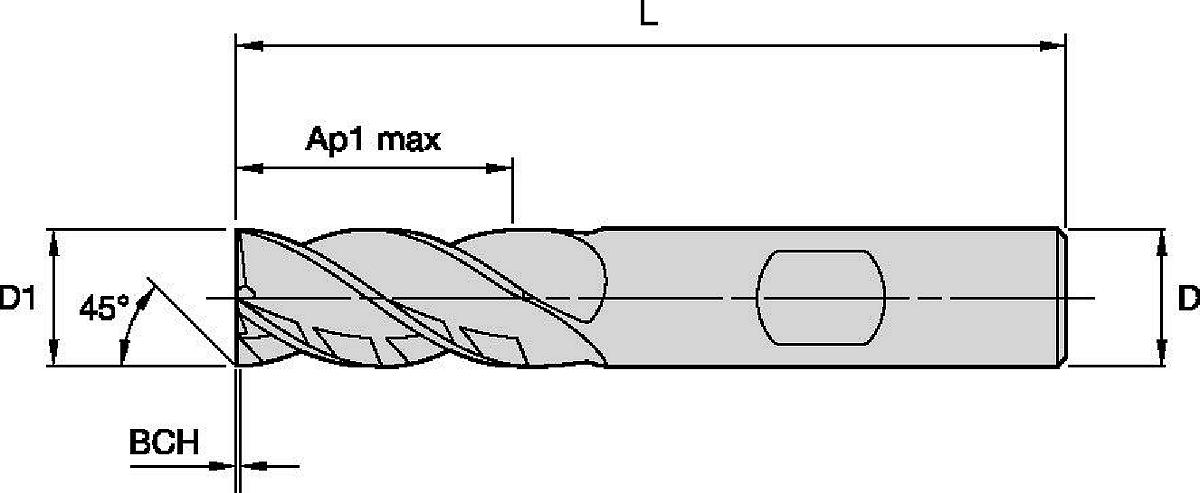

Cutting edges are only on a top. It is measured from the start of the necked portion to the bottom of the cutting end of the tool. Tool Holder Tightening Fixture.

End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material. Producing a uniform product prior to hot mill finishing ensures better quality and yield in final products downstream. Most are Titanium Aluminum Nitride TiAlN coated but the larger 2-inch roughers are uncoated.

Figure 7 shows the tool wear of the end mill after about 0 10 and 20 hours passed in real gear machining. The idea is to rough out a pocket profile or 3D surface by plunging either a twist drill an end mill or a special-purpose tool straight down into the material. Diagram of an end mill.

End mill A multi-functional tool which has cutting edges on the periphery and an end face. These figures should be viewed in the context of Figure 3. 2 roughing mill in CSC and are summarized in.

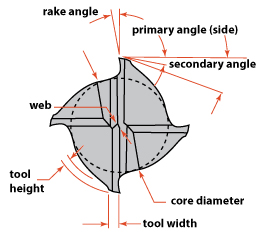

Diagram of an end mill. The rolling parameters were adopted from the No. Endmill Design Basics Angular Edge The cutting edge that is a straight line and forms an angle with the cutter axis.

Milling tests under roughing conditions were carried out with different tool holder systems at variable spindle speeds and acceleration data captured during milling. Destiny end mills also form a manageable 6 and 9 shaped chip by traveling down through the gullet to the core diameter of the end mill. Drill A tool for drilling.

These general-purpose roughers are designed for high-production metal removal in a wide range of workpiece materials. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. Two High Rolling Mills.

Accurate length and speed measurements at the roughing mill require a well-engineered reliable system due to the harsh environment that these gauges must operate in. This reduces chatter and vibration which could otherwise be larger because of the jagged teeth. 66 μm after about 10 hours passed.

Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project. The cut that an Angular edge tool produces will not be as flat as a helical cutting edge. The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools.

Since the radial relief angle of end mill is 11 degree the diminution Δr of radius of end mill is 34 μm tan 11 deg. For fast cuts and the greatest rigidity use shorter end mills with larger diameters.

Basic End Mills Technical Information Msc Industrial Supply Co

End Milling An Overview Sciencedirect Topics

Basic End Mills Technical Information Msc Industrial Supply Co

Solid Carbide End Milling Harvi I Te Four Flute End Mill For Roughing And Finishing Covering The Broadest Range Of Applications And Materials

Roughing End Mills रफ ग ए ड म ल In Midc Bhosari Pune Orient Tools Id 3666888530

Solid Carbide End Milling Harvi Ii Solid Carbide End Mill For Roughing And Finishing Of Multiple Materials

Roughing Chip Breaker Bits 4 Flute F4zc45 End Mills Drills Frezycnc Eu

End Mill An Overview Sciencedirect Topics

Carbide Square End Mill 4 Flute 2d Flute Length Short Model Misumi Misumi

End Mill An Overview Sciencedirect Topics

Roughing End Mill Kyocera Unimerco

4 Flute End Mills For Hardened Steel End Mills Drills Frezycnc Eu

End Milling An Overview Sciencedirect Topics

8 Ways You Re Killing Your End Mill In The Loupe

The Secret Mechanics Of High Feed End Mills In The Loupe

End Mills Cad Cam Engineering Worldwide

Endmill Design Basics Mastercut Tool Corp

Schematic Diagram Of The Side Milling Process Download Scientific Diagram